SISMO PRODUCTION STATION (SPS)

A full SPS is a production line that functions independently. Production starts from steel wire coils and EPS blocks available on most regional markets.

One complete SPS includes:

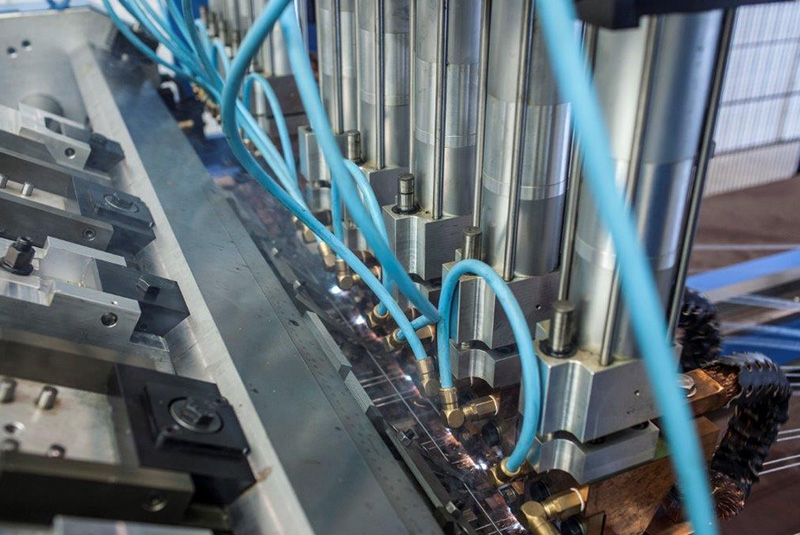

- One SISMO Production Station, hardware consisting of three major components the 1D, 2D and 3D machines.

- One set of polystyrene processing equipment (3D Block cutter; TGM, Tongue and Groove Mill; PMM for the SISMO flooring system)

- One set of auxiliary equipment for the SISMO module filling station

- The SISMO propriety software sisCAD®

- Training for the sisCAD® designer

- Training for the line operators of the SPS

- Training for on-site assembly

- Technical assistance for factory installation and start up

SISMO building technology

- Transfer of technology, SISMO building technology (SBT)

- Exclusive regional licens

- License for the use of the registered trade name and trademark.

- License for the sisCAD® software. Fingerprints for installation and usage of the software. Corrective, adjusting and innovative maintenance to the sisCAD® software.

- Continuous support, technical assistance and training.